|

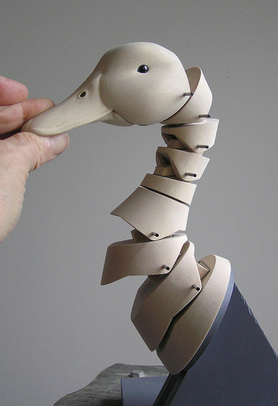

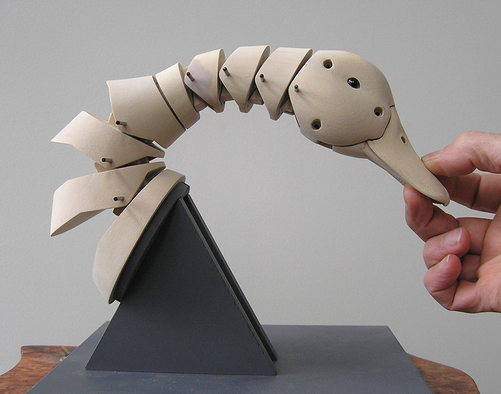

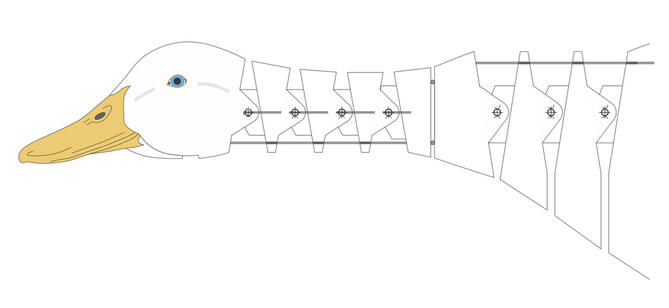

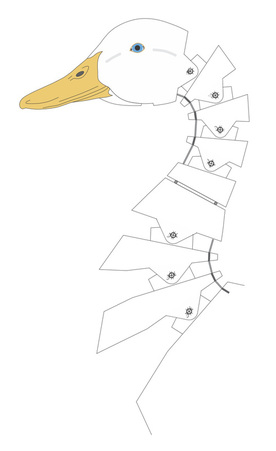

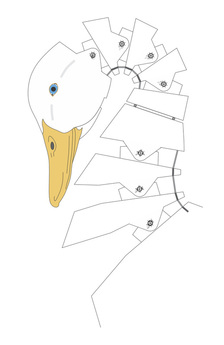

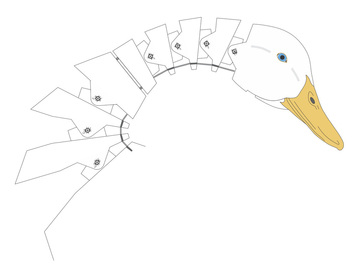

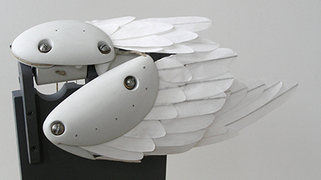

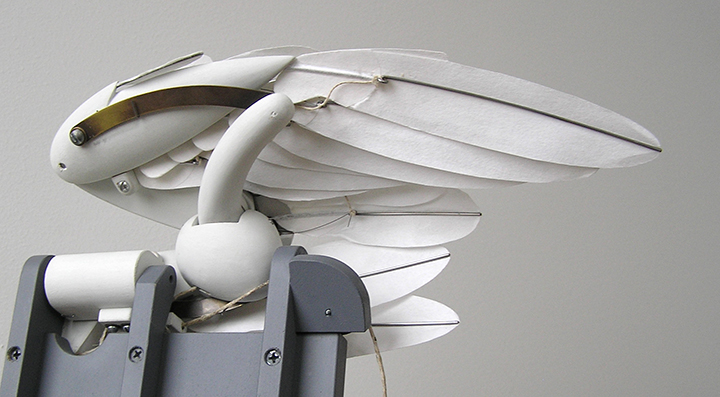

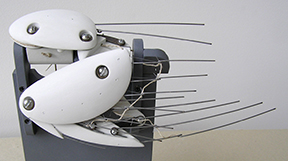

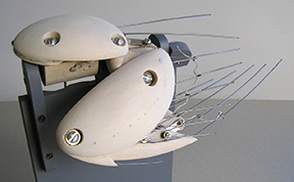

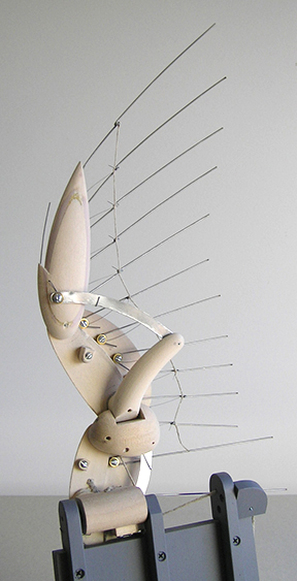

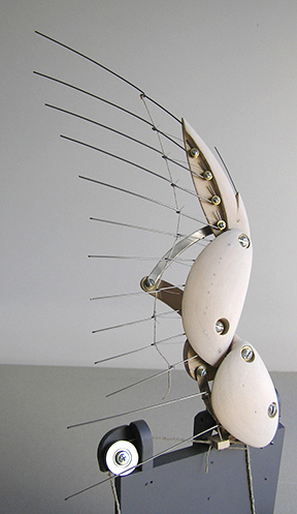

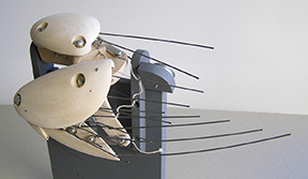

The upper neck is roughed-out and works!

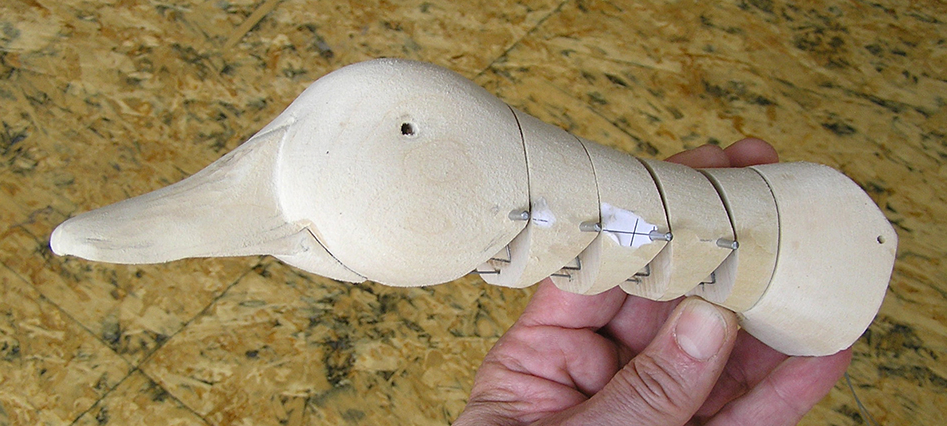

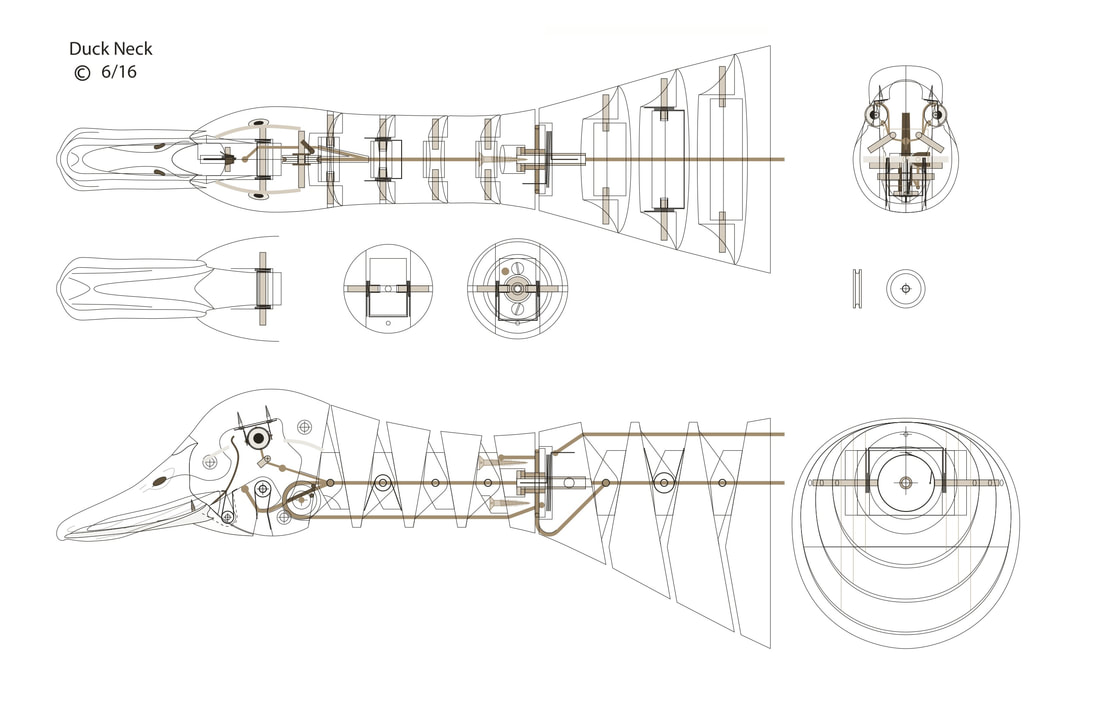

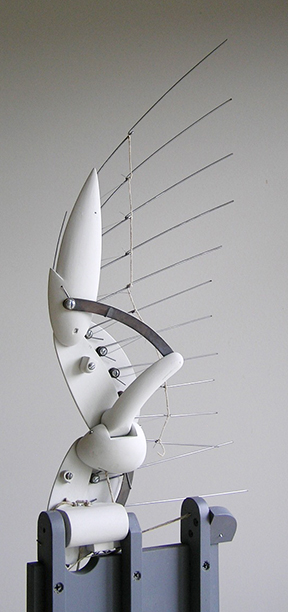

One string bends the upper neck downward, a second string swivels the upper neck back & forth and a third string opens & closes the beak. After building most of the prototype for the upper neck I realized the overall size was too small.

I was able to arrange to measure a frozen duck specimen with feathers at the Burke museum (thank you Carl Sander & Robert Faucett) and revised the design to actual duck scale. Other design changes were made to reflect what I learned building the prototype. The duck's neck is now ready to build. I've been thinking about and sketching neck ideas since the 80's. Over the years I've come up with a variety of solutions and made a few simple mock-ups to see how they work. After rejecting the ones that are overly complex or simply wouldn't work, I've arrived at a design that's ready to try. We'll see how reality impacts.

|

Progress of the Mechanical Duck

Donations of any amount to the Mechanical Duck are greatly appreciated. They are used to open up time to move the

project along. Thank you! |